… its page name has probably just changed.

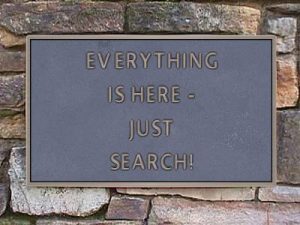

Find what you want by:

- SEARCHING using the search box in the upper righthand corner of your screen.

- Checking out the SITE MAP, where every page is listed.

- Visiting the HOMEPAGE to find the new and improved version.

If you have any questions, email us at info@kevincaron.com or call 602-952.8767.

Thanks!